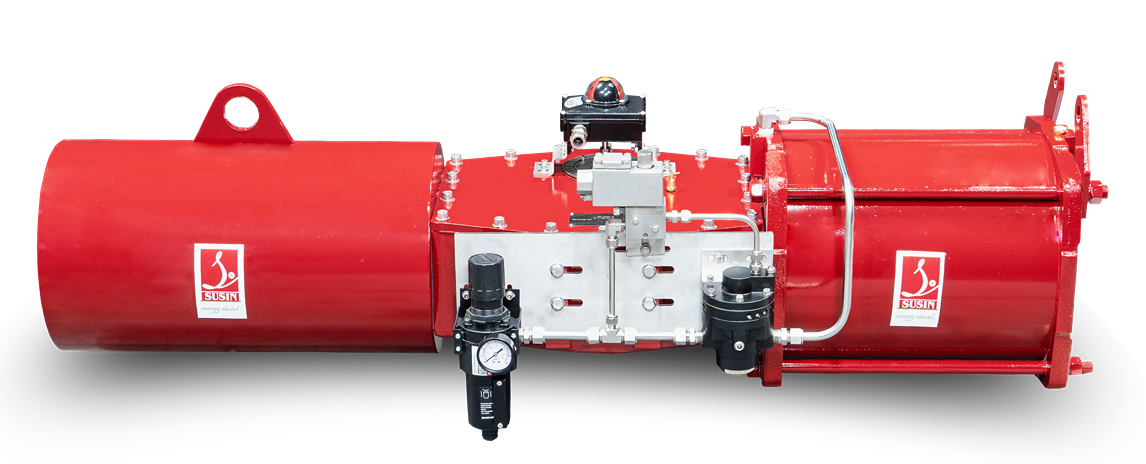

Pneumatic Actuators

We specialize in providing the best & reliable flow control solutions in the most challenging environments.

Essential Role of Actuators in Modern Water Treatment Plants

Essential Role of Actuators in Modern Water Treatment Plants

Published by SUSIN GROUP | Engineering Insights

Introduction

Water treatment plants are the backbone of public health and industrial sustainability, ensuring clean, safe, and compliant water supply across sectors. Behind the scenes, one critical component ensures reliable flow control at every stage of treatment: the valve actuator. From opening intake gates to managing chlorine dosing, actuators play a pivotal role in optimizing operations, improving efficiency, and enabling automation.

Why Actuators Matter in Water Treatment

Water treatment processes involve multiple stages—coagulation, sedimentation, filtration, disinfection, and storage. Each of these requires precise control of water flow and chemical dosing. Manual valve operation is prone to error, delays, and safety hazards. That’s where pneumatic and electric actuators come into play.

Key Functions:

- Automated Flow Regulation – Maintain exact flow rates through filters and tanks.

- Chemical Dosing Precision – Ensure accurate chlorine or pH adjustments.

- Remote Operation – Allow control from SCADA or control rooms, minimizing manual intervention.

- Emergency Shutdown – Enable fail-safe closure in case of leak detection or power failure.

Actuator Types Used in Water Plants

Choosing the right actuator depends on the valve type, application, and environmental condition:

| Actuator Type | Common Applications | Advantages |

|---|---|---|

| Pneumatic | Sedimentation basins, inlet gates | Fast operation, fail-safe via spring |

| Electric | Chlorine dosing, outlet valves | Energy-efficient, precise control |

| Hydraulic | Dam or high-pressure control valves | High force applications |

Smart Actuators: Driving Digital Transformation

Modern water plants are adopting smart actuators integrated with IoT and SCADA systems. These devices provide:

- Live Feedback – Valve position, torque, temperature, and alarms.

- Predictive Maintenance – Alerts for wear, misalignment, or pressure anomalies.

- Data Logging – Store operational metrics for compliance and audits.

SUSIN’s smart actuators are built with optional Bluetooth and Modbus support, allowing seamless integration with water utility control systems.

Real-World Use Case

In a municipal water treatment facility in Tamil Nadu, SUSIN’s spring-return pneumatic actuators were deployed across sedimentation tank inlets. With consistent flow regulation and remote operability, the plant achieved:

- 18% reduction in process interruptions

- 23% improvement in chemical usage accuracy

- Full SCADA integration for valve health monitoring

Key Considerations for Water Plant Engineers

- IP Rating: Use IP67-rated enclosures in outdoor or washdown zones.

- Material Compatibility: Choose stainless steel or coated aluminum for high-chlorine environments.

- Fail-Safe Design: Spring-return options ensure safe closure during power or air loss.

As water treatment demands grow and regulatory norms tighten, actuators will only increase in importance. Whether it’s ensuring uninterrupted flow or enabling remote diagnostics, the right actuator can transform plant performance.

SUSIN offers a wide range of pneumatic, electric, and smart actuators designed for water industry needs.

🔗 Related Links:

- Explore Our Pneumatic Actuators

- Download Valve Selection Guide for Water Plants

- Request a Free Actuator Sizing Consultation

-

Post Tags:

Post Tags: - Butterfly Valves

- Actuators

- Scotch yoke Actuators

- Gearboxes