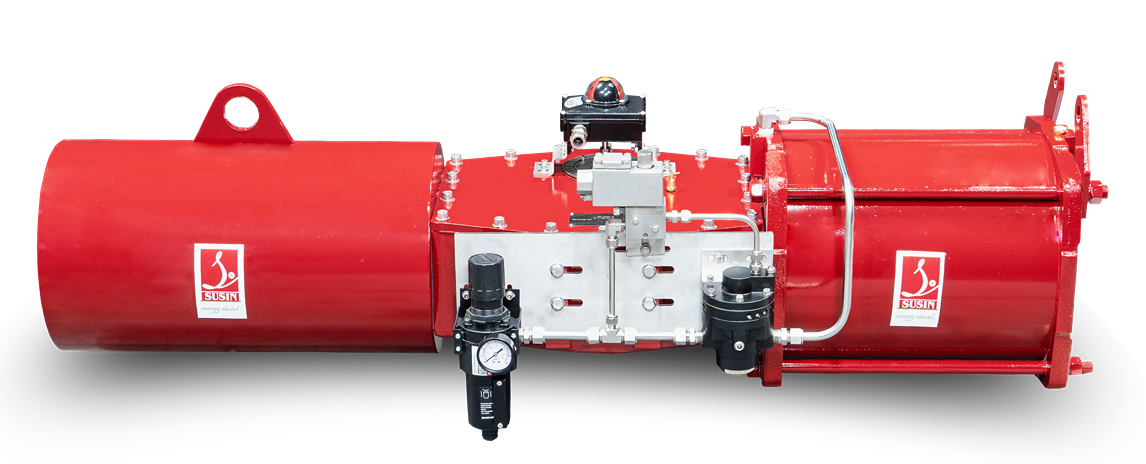

Pneumatic Actuators

We specialize in providing the best & reliable flow control solutions in the most challenging environments.

Rotary Actuators in FGD Systems: Reliable Damper Automation for Emission Control

Rotary Actuators in FGD Systems: Reliable Damper Automation for Emission Control

Published by SUSIN GROUP | Power & Environment Series

Introduction

As environmental regulations tighten across the globe, Flue Gas Desulfurization (FGD) systems have become mandatory in coal-fired power plants and industrial boilers. One of the most critical components in FGD systems is the damper, which regulates the flow of flue gas across scrubbers, absorbers, and bypass paths.

To ensure precise, fail-safe, and corrosion-resistant operation of these dampers, SUSIN Rotary Actuators are the ideal solution.

The Role of Dampers in FGD Systems

FGD systems remove sulphur dioxide (SO₂) from exhaust gases using chemical absorbers (usually limestone slurry). To manage this process efficiently, multiple dampers are installed to:

- Isolate the FGD unit during start-up/shutdown

- Control flow across scrubbers and bypass lines

- Balance pressure and gas distribution

- Protect equipment during overload or trips

Manual operation is risky and inefficient—automated rotary actuators are essential.

Why SUSIN Rotary Actuators Are Built for FGD Dampers

SUSIN’s pneumatic rotary actuators (HDS and PDS Series) are engineered to withstand the harsh conditions of flue gas environments.

✅ Key Features:

- High Torque Output (up to 28,000 Nm)

→ Suitable for large and heavy-duty guillotine or multi-louver dampers. - Corrosion-Resistant Construction

→ Coated Aluminum or SS316 housing with epoxy paints protect against SO₂-laden gas exposure. - Precise Modulating Control

→ Quarter-turn accuracy with fine torque control for gas flow regulation. - Fail-Safe Operation

→ Spring Return variants ensure automatic damper closure during emergency or air failure. - Temperature & Dust Tolerance

→ Operating ranges from -20°C to +85°C and dust-sealed designs (IP65/IP67 optional).

Case Application: Power Plant FGD Retrofit

At a 660 MW thermal power plant in Eastern India, SUSIN PLS-Series actuators were deployed on bypass and absorber inlet dampers during an FGD retrofit project.

🚀 Results:

- Reduced manual intervention by 100%

- Achieved full SCADA-based actuator control

- Damper response time improved by 40%

- All actuators operated continuously for 14 months without shutdown or maintenance

Integration with Control Systems

SUSIN actuators are compatible with:

- ON-OFF & Modulating Control Signals (4–20 mA, digital I/O)

- Fieldbus/SCADA/DCS Systems

- Position Feedback Sensors & Limit Switches

We also offer declutch able gear override for manual control during system commissioning or testing.

Choosing the Right Actuator for Your Dampers

| Damper Type | Recommended Actuator Series | Notes |

|---|---|---|

| Guillotine Damper | PDS Series | Double Acting for large stroke |

| Louver/Baffle Damper | PLS Series (Spring Return) | Fail-safe gas control |

| Stack Isolator | PLS with Manual Override | Emergency shutdown function |

FGD dampers are mission-critical for emission control. Choosing the right actuator ensures not only regulatory compliance but also system efficiency and plant safety.

SUSIN Rotary Actuators offer the reliability, torque, and environmental protection needed for today’s FGD automation challenges.

📥 Ready to Upgrade Your FGD Damper Control?

- 🔗 Download SUSIN Actuator Selection Guide

- 📞 Request a Free Site Audit

- 💡 Talk to Our Application Engineers

-

Post Tags:

Post Tags: - Butterfly Valves

- Actuators

- Scotch yoke Actuators

- Dampers