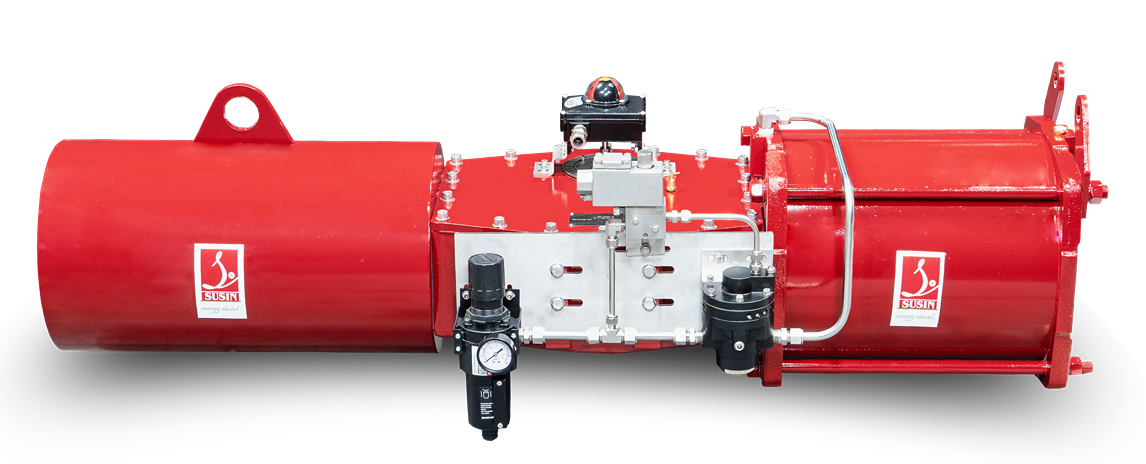

Pneumatic Actuators

We specialize in providing the best & reliable flow control solutions in the most challenging environments.

Reliable Rotary Actuators for FPSO Projects: Enhancing Safety and Control Offshore

Reliable Rotary Actuators for FPSO Projects: Enhancing Safety and Control Offshore

Published by SUSIN GROUP | Offshore & Marine Series

Introduction

Floating Production Storage and Offloading (FPSO) vessels are critical assets in offshore oil and gas production, combining processing, storage, and offloading functions in a single floating unit. Due to the extreme marine environment and complex process needs, the choice of valve actuation systems is vital for ensuring operational safety, efficiency, and reliability.

SUSIN Rotary Actuators have been extensively deployed across FPSO projects worldwide to automate valves and dampers, providing precise, corrosion-resistant, and fail-safe performance under challenging conditions.

The Unique Challenges of FPSO Valve Automation

FPSO environments expose equipment to:

- High humidity and saltwater corrosion

- Vibration and motion due to waves and loading

- Hazardous zones requiring explosion-proof (Ex) rated devices

- Limited maintenance accessibility offshore

- Stringent safety and operational uptime requirements

Selecting robust, certified actuators capable of withstanding these demands is non-negotiable.

Why Choose SUSIN Rotary Actuators for FPSO Applications?

SUSIN offers a range of pneumatic and electric rotary actuators tailored for the offshore environment:

🌊 Marine-Grade Construction

- Corrosion resistant materials: SS316 and coated aluminum bodies with epoxy finishes

- IP66/IP67 rating ensures protection against salt spray and moisture ingress

- High vibration and shock resistance engineered for FPSO dynamic loads

🔥 Explosion-Proof & Certified Designs

- Actuators certified for Zone 1/Zone 2 hazardous areas (ATEX, IECEx)

- Customizable sealing and ingress protection options

- Compliance with offshore regulatory standards

⚙️ High Torque & Precision Control

- Torque range from 100 Nm up to 1,50,000 Nm (custom solutions beyond available)

- Quarter-turn accuracy for valves such as ball, butterfly, and plug valves

- Optional modulating control with feedback signals for SCADA integration

🔄 Fail-Safe Spring Return Options

- Critical for emergency shutdown valves (ESD) and emergency depressurization systems

- Spring-return actuators automatically drive valves to a safe position on power or air loss

Case Study: FPSO Valve Automation in the Arabian Sea

A leading FPSO operator in the Arabian Sea retrofitted SUSIN pneumatic actuators on over 50 critical valves, including subsea injection valves and flare system dampers.

Project Highlights:

- Achieved 100% uptime with zero actuator failures over 24 months

- Improved valve response times by 35%, enhancing process control

- Full integration with vessel control system using Modbus communication

- Successful ATEX Zone 1 certification facilitated safe offshore operation

Integration & Support for Offshore Projects

SUSIN provides full technical support for FPSO projects:

- Engineering consultation for actuator sizing & selection

- Customized paint coatings and Ex certifications

- Field service and commissioning support on-site or remote

- Spare parts and retrofit solutions for existing valve packages

Summary: Why SUSIN Is Your Trusted FPSO Actuator Partner

| Feature | Benefit for FPSO Projects |

|---|---|

| Marine-grade corrosion resistance | Long service life in harsh marine environments |

| Explosion-proof certification | Compliance with offshore safety regulations |

| Wide torque range | Suitable for all valve sizes and functions |

| Fail-safe spring return | Critical for emergency shutdown & safety |

| SCADA & DCS compatibility | Real-time monitoring and control |

Ready to Optimize Your FPSO Valve Automation?

📞 Contact SUSIN for a tailored actuator solution that meets your offshore project’s rigorous demands.

🔗 Download FPSO Actuator Selection Guide

📧 Email: sales@susinitork.in

🌐 Website: www.susingroup.com

-

Post Tags:

Post Tags: - Actuators