Pneumatic Actuators Overview

Susin Group’s Pneumatic actuators are engineered to provide reliable, high-torque valve automation solutions for industrial processes. Utilizing compressed air power, these actuators are ideal for quarter-turn valves such as ball, butterfly, and plug valves, offering fast response times and robust performance in demanding environments.

Product Range

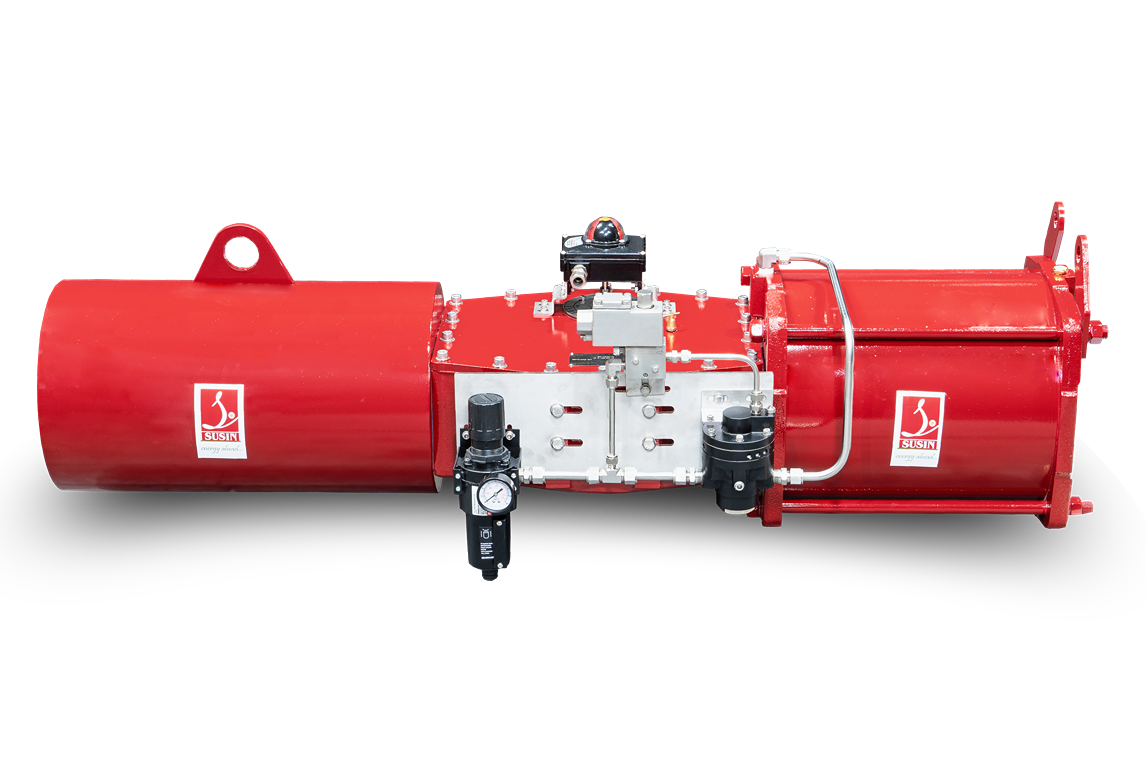

• Scotch Yoke Pneumatic Actuators:

Designed for applications requiring high torque with compact size, our Scotch Yoke actuators convert linear piston movement into smooth rotary motion, ensuring consistent valve operation under heavy loads. Perfect for oil & gas, chemical processing, and power plants.

• Double Acting and Spring Return Piston Type Linear Cylinder Models:

Double acting models provide precise open/close control with air pressure in both directions, while spring return actuators use internal springs for automatic valve closure on air failure, enhancing safety.

Technical Highlights

• Operating pressure: Typically, 2 to 8 bar (29 to 116 psi)

• Torque range: From 10 Nm up to 1,50,000 Nm for large valves requirements

• IP ratings: IP-65, IP-67M and IP-68 for dust and water resistance

• Certifications: SIL-3, PED, ATEX, IECEx for hazardous areas compliance

Benefits

• Rapid actuation and high cycle life of operations.

• Minimal maintenance due to rugged design construction.

• Modular design for easy mounting and customization

• Compatible with a wide variety of valve types and sizes

Typical Applications

• Oil & Gas pipelines and terminals

• Petrochemical plants

• Power generation stations

• Water and wastewater treatment facilities

• Food & beverage processing

Frequently Asked Questions (FAQ)

1: What are the main advantages of pneumatic actuators?

A: Pneumatic actuators are simple, reliable, and provide fast response times with high force output using compressed air. They are well-suited for hazardous environments since they do not use electricity.

2: What is the difference between double acting and spring return actuators?

A: Double acting actuators use air pressure for both opening and closing the valve, while spring return actuators use air pressure to open and a spring to return the valve to its default position when air pressure is lost, providing fail-safe operation.

3: Are your pneumatic actuators suitable for hazardous areas?

A: Yes, we offer ATEX and IECEx certified pneumatic actuators designed specifically for safe operation in hazardous and explosive environments.

Contact Us

For more information about our Pneumatic Actuators or to discuss your specific requirements, please contact us.